AMS 5655 UNS S42200 Alloy 422 stainless steel rod supplier, 422 stainless steel wire rod in stock

▪ Aircraft parts

▪ Steam and gas turbine components

▪ High heat components

▪ Rotors

Large sections should be preheated to 1200/1400ºF (650/760ºC), then to 1900/2150ºF (1040/1175ºC). Forgings should be slow cooled and annealed or tempered as soon as possible after reaching room temperature.

Hardening should not be attempted without an inter anneal or preheat in the range 1200/1400ºF (650/760ºC.)

ANNEALING:

Heat to 1350/1430ºF (730/780ºC) and soak for 4 hours, then furnace or air cool. The resulting hardness will be Rc21-25 and the microstructure tempered martensite. Or isothermal anneal by heating to 1900ºF (1040ºC), cooling to 1275ºF (690ºC) and holding for 24-48 hours and air cooling. This treatment will give a hardness of Rb90-95 and a structure of ferrite plus carbide. Following an iso anneal the part must be re-hardened (1900/1950ºF (1040/1065ºC) and tempered to required mechanical properties.

HARDENING:

Heat to 1900ºF (1040ºC), soak and oil quench to a resulting hardness of Rc45/50. Intricate shapes may be marquenched to 650ºF (340ºC) and air cooled. Parts should not be air cooled to the Ms temperature and quenched as this will likely cause cracking.

Parts should be cooled to room temperature before tempering. Complete transformation to martensite is necessary to prevent non-uniform structures and hardness after tempering.

TEMPERING:

Past experience should be used to determine tempering temperatures required to attain desired mechanical properties. It is preferable to temper straight after parts reach room temperature from hardening.

MACHINABILITY:

The alloy is readily machined in the annealed condition: it machines as 420 stainless steel.

WELDABILITY:

Welding of this alloy is difficult, due to cracking. Preheating, and a post-weld stress relief of the welded areas at 1100/1400ºF (590/760ºC) for 4 hours are recommended.

Best corrosion resistance is obtained in the hardened and tempered condition.

| C | 0.23 max | Mn | 0.7 max |

| Si | 0.35 max | Mo | 1.0 max |

| Cr | 11.5 max | Ni | 0.8 max |

| W | 1.0 max |

| Tensile strength MPa(min) | Yield strength MPa(min) | Elongation % | Hardness HB MAX |

| 897 | 207 | 15 | 190 |

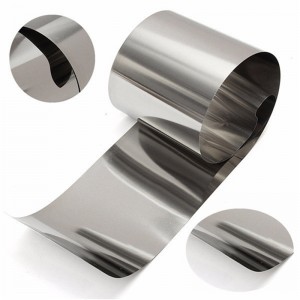

| 422 stainless steel strip sizes and specifications | |

| Grade | 422 |

| Cold rolled stainless steel strip | Thickness: 0.3mm- 3.0mm, Width: 5mm - 900mm, Surface: 2B/BA/SB/8K/HL/1D/2D etc |

| Hot rolled stainless steel strip | Thickness: 3.0mm - 16mm, Width: 10mm - 900mm Surface: No.1/pickling |

| Stainless steel foil | Thickness: 0.02mm- 0.2mm, Width: Less than 600mm, Surface: 2B |

| Standard | ASTM A240/A480, ASTM B688, ASTM B463/SB463, ASTM B168/SB168, ASTM B443/SB443/B424/SB424B625/SB625 B575/SB575, JIS G4303, BS 1449, DN17441, G4305 |

| 422 stainless steel coil sizes and specifications | |

| Grade | 422 |

| Cold rolled stainless steel coil | Thickness: 0.3mm- 3.0mm, Width: 1000mm - 2000mm, Surface: 2B/BA/SB/8K/HL/1D/2D etc |

| Hot rolled stainless steel coil | Thickness: 3.0mm - 16mm, Width: 1000mm - 2000mm Surface: No.1/pickling |

| Standard | ASTM A240/A480, ASTM B688, ASTM B463/SB463, ASTM B168/SB168, ASTM B443/SB443/B424/SB424B625/SB625 B575/SB575, JIS G4303, BS 1449, DN17441, G4305 |

| 422 stainless steel pipe sizes and specifications | |

| Grade | 422 |

| Stainless steel seamless pipe | Outside diameter: 4.0 - 1219mm, Thickness: 0.5 -100mm, Length: 24000mm |

| Stainless steel welded pipe | Outside diameter: 6.0 - 2800mm, Thickness: 0.3 -45mm, Length: 18000mm |

| Stainless steel capillary pipe | Outside diameter: 0.4 - 16.0mm, Thickness: 0.1 -2.0mm, Length: 18000mm |

| Stainless steel welded sanitary pipe | Outside diameter:8.0- 850mm, Thickness: 1.0 -6.0mm |

| Stainless steel seamless sanitary pipe | Outside diameter: 6.0- 219mm, Thickness: 1.0 -6.0mm |

| Stainless steel square pipe | Side Length: 4*4 - 300*300mm, Thickness: 0.25 - 8.0mm, Length: 18000mm |

| Stainless steel rectangular pipe | Side Length: 4*6 - 200*400mm, Thickness: 0.25 - 8.0mm, Length: 18000mm |

| Stainless steel coil pipe | Outside diameter: 0.4 - 16mm, Thickness: 0.1 - 2.11mm |

| Standard | American Standard: ASTM A312, ASME SA269, ASTM A269, ASME SA213, ASTM A213 ASTM A511 ASTM A789, ASTM A790, ASTM A376, ASME SA335, B161, SB163, SB338, SB667/668 Germany Standard: DIN2462.1-1981, DIN17456-85, DIN17458-85· European Standard: EN10216-5, EN10216-2 Japanese Standard: JIS G3463-2006, JISG3459-2012 Russian Standard: GOST 9941-81 |

| 422 stainless steel profile sizes and specifications | |

| Grade | 422 |

| Specification | EN, DIN, JIS, ASTM, BS, ASME, AISI, ISO |

| Standard | ASTM A276/ASME SA276, ASTM A479/ASME SA479 & ASTM A164/ASME SA164 . |

| Stainless steel round Bar | Diameter: 2mm - 600mm |

| Stainless steel bright Bar | Diameter: 2mm - 600mm |

| Stainless steel hex Bar | Dimension: 6mm - 80mm |

| Stainless steel square bar | Dimension: 3.0 - 180mm |

| Stainless steel flat bar | Thickness: 0.5mm - 200mm, Width: 1.5mm - 250 mm |

| Stainless steel angle bar | as requirements |

| Length | Normally 6m, or produce as requirements |

| Surface | Black, Bright. Peeled and Polished, Solution annealed. |

| Delivery condition | cold drawn, hot rolled, forged, grinding, centerless grinding |

| Tolerance | H8, H9, H10, H11, H12, H13,K9, K10, K11, K12 or as per clients’ requirements |

| 422 stainless steel plate sizes and specifications | |

| Grade | 422 |

| Cold rolled stainless steel plate | Thickness: 0.3mm- 16.0mm, Width: 1000mm - 2000mm, Length: as requirements, Surface: 2B/BA/SB/8K/HL/1D/2D etc |

| Hot rolled stainless steel sheet | Thickness: 3.0mm - 300mm, Width: 1000mm - 3000mm Length: as requirements, Surface: No.1/pickling |

| Standard | ASTM A240/A480, ASTM B688, ASTM B463/SB463, ASTM B168/SB168, ASTM B443/SB443/B424/SB424B625/SB625 B575/SB575, JIS G4303, BS 1449, DN17441, G4305 |

| Stainless steel plate | Thickness: 8.0mm - 300mm, Width: 1000mm - 3000mm Length: as requirements, Surface: No.1/pickling |